Jenitek provides value through each step of the project. Whether supplement your capabilities or carry out the entire project, we are ready to assist you from concept through production, to your customer’s door. With access to dozens of post-production processes, we can shorten the waiting time for products to enter the market, reduce manufacturing costs and improve product quality.

Here is a list of our secondary operations:

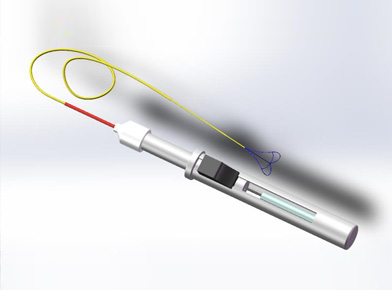

l Cleaning & Passivation l Electropolishing & Anodization l Tumbling & Micro Blasting l Grinding & Deburring l Magnetic Blasting l Plating l Heat Treating l Glue Bonding | l Laser Welding l Laser Marking l Laser Cutting and Drilling l Micro Injection Molding l Micro Coiling l Pad & Screen Printing l Packaging & Labeling l Sub-Assemblies & Complete Device Assembly |

Advantages:

l ISO13485:2016 certified

l FDA registered

l ISO Class 7 and Class 8 cleanrooms

l Complete device history recordkeeping

l ASQ certified Six Sigma black belt team

l IQ/OQ/PQ validations

Applications of our products:

Scope of application |

Examples |

Vascular Surgery |

Intravascular ultrasounds, Stents, Guidewires, Catheters, Balloons, Vena cava filters, Artificial blood vessels

|

Ocular & Otorhinolaryngology (ENT) Surgery |

Ocular drainage implants, Ossicular prosthesis, Rhinoscopy, Laryngoscopy |

Nerve Intervention and Implantation |

Micro guide wires, Micro catheters, Spring coils, Stent systems, Intravascular balloons |

Endoscopic Surgery

|

Rhinoscopy, Laryngoscopy, Otoscopy, Bronchoscopy, Laparoscopy, Enteroscopy, Colonoscopy, Hysteroscopy |